It is time to solder through-hole and surface-mounted components.

I use Chip Quick solder paste for SMT components. When not in use, keep it in the freezer to extend its shelf life (it should not dry up). Chip Quick has a very low melting point and it’s perfect to use for SMT since you can apply tiny drops of it through a syringe it comes with. Apply small drops to pads and then position SMT components on them using tweezers.

An interesting thing happens when you solder SMT components by using a hot air station: as the solder paste gets hot and the liquid part starts to boil out, SMT parts start moving, and then they perfectly self-align with the pads they are on.

When you start the fan to blow the hot air, don’t set it too high – it can blow the components away!

If you get solder bridges across small pins, use a wick to suck them out. Use plenty of wicks. It is useful to have several wicks at hand so you can keep going uninterrupted and then take time to cut them off when done. You can run through wicks quickly; always have extra.

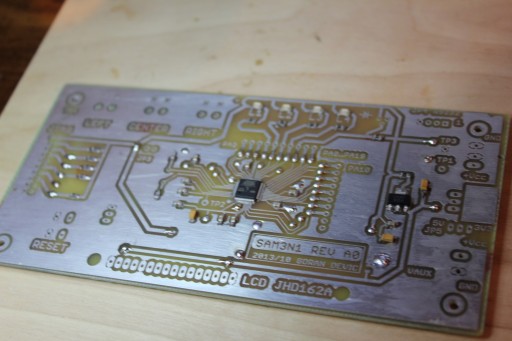

This image shows tools used for PCB soldering and mounting parts for this project.

Tools: Soldering wick, solder, soldering iron, loupe with light, fine (SMD) tweezers, scissors, pliers, Exacto knife,…?

Advanced tools: SMD rework station (hot air station), Chip Quick solder paste, wire stripper