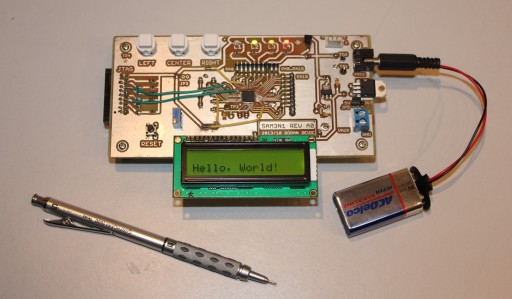

This set of short articles will show you the making of a PCB, from the initial requirement stage, through the design and manufacture, and to final software programming.

If you are new to PCB making, I am hoping this text should paint some basic picture of what is involved in a home board design and manufacture. If you are already an experienced hobbyist, I hope you will find some parts informative or interesting enough to try them yourself on your next project. If you see anything wrong or have a better way of doing it, please post it in a comment. I will appreciate learning from you and sharing the experience!

Continue reading